Hardware

Wooden Paper With Accessories

It’s the Processes Where any Steel Material Could be made look alike like a wood (M.S, G.I, S.S, Alluminium)

The Processes Starts with Spraying a Polypropene Powder on a surface of a job or Metal which need to be Look like wooden, after spraying its heated in Oven for 15-18 Minutes at a Temperature of 220 degree celusis, then the Job is Glued with an tranparent Glue in order to stick the wooden paper. Once the paper is sticked then its again heated in oven at 180 degree celusis for 15 minutes, where colur from paper is transferred to the metal or job. And effective results is obtained.

Wooden Base Paper

Wooden Base Paper

Wooden Base Paper

Wooden Base Paper

Hinges

Hinges are essential hardware components used to connect two solid objects, allowing them to rotate relative to each other. They are commonly found in doors, cabinets, gates, and other applications where controlled movement is required. Hinges come in various types, each designed for specific purposes and load capacities.

Specifications

-

Material S.S Steel door

-

Max. door weight for 2 hinges. 15.0 kg.

-

Area of application. For steel frames, for flush steel interior doors.

-

Opening angle. 180.0 °

-

Swing action. two-sided.

-

Hold-open angle. 110 °

-

Mounting. For DIN left and DIN right hand use.

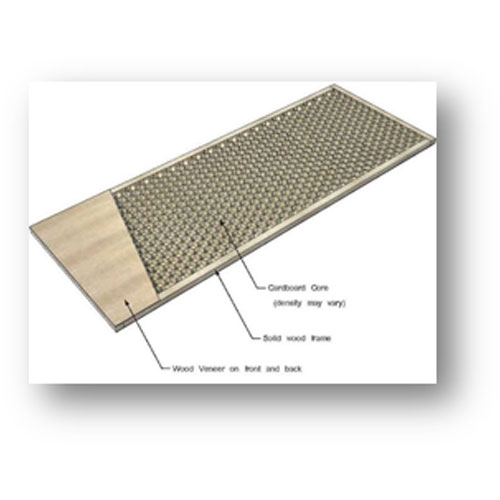

Honey Comb

Honeycomb used in inside the steel door and they are known for the longevity, outlasting Their resistance to bending pressure and flat surfaces reduces the likelihood of deformation over time. Despite their lightweight appearance, honeycomb doors are remarkably durable.

-

Durability and Longevity : Honeycomb cores contribute to the longevity of steel doors by providing a structure that resists deformation, bending, and pressure. This makes the doors more robust over time.

-

Lightweight Strength : Despite being lightweight, honeycomb cores are known for their strength. They add structural integrity to the door without adding significant weight, making the door easier to handle and install.

-

Resistance to Bending and Deformation : The flat surfaces of honeycomb structures help maintain the door's shape, reducing the likelihood of warping or bending over time, even under pressure.