Cable Tray

Introduction

A cable tray system is used to support insulated electric cables used for power distribution & communication. Cable trays are used as an alternative to open wiring or electrical conduit system,& are commonly used for cable management in commercial and industrial construction. They are especially useful in situations where changes to a wiring system are anticipated ,since new cables can be installed by laying them in the tray, instead of pulling them through a pipe.

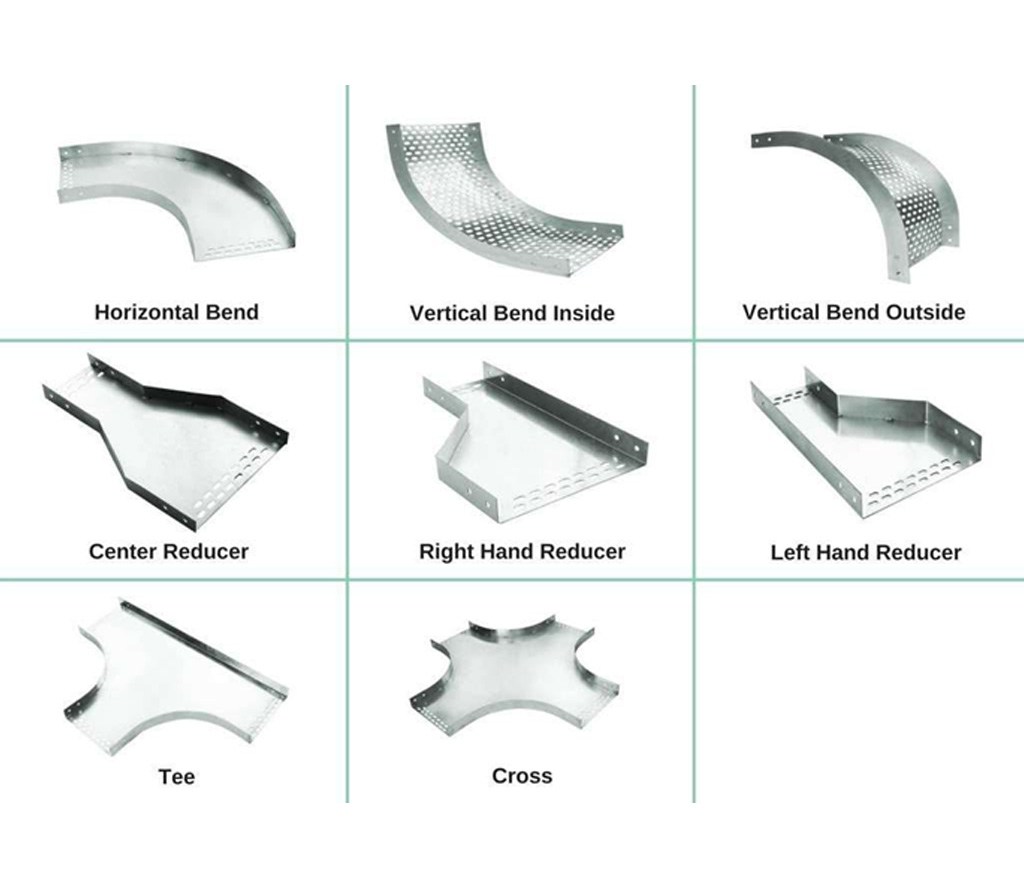

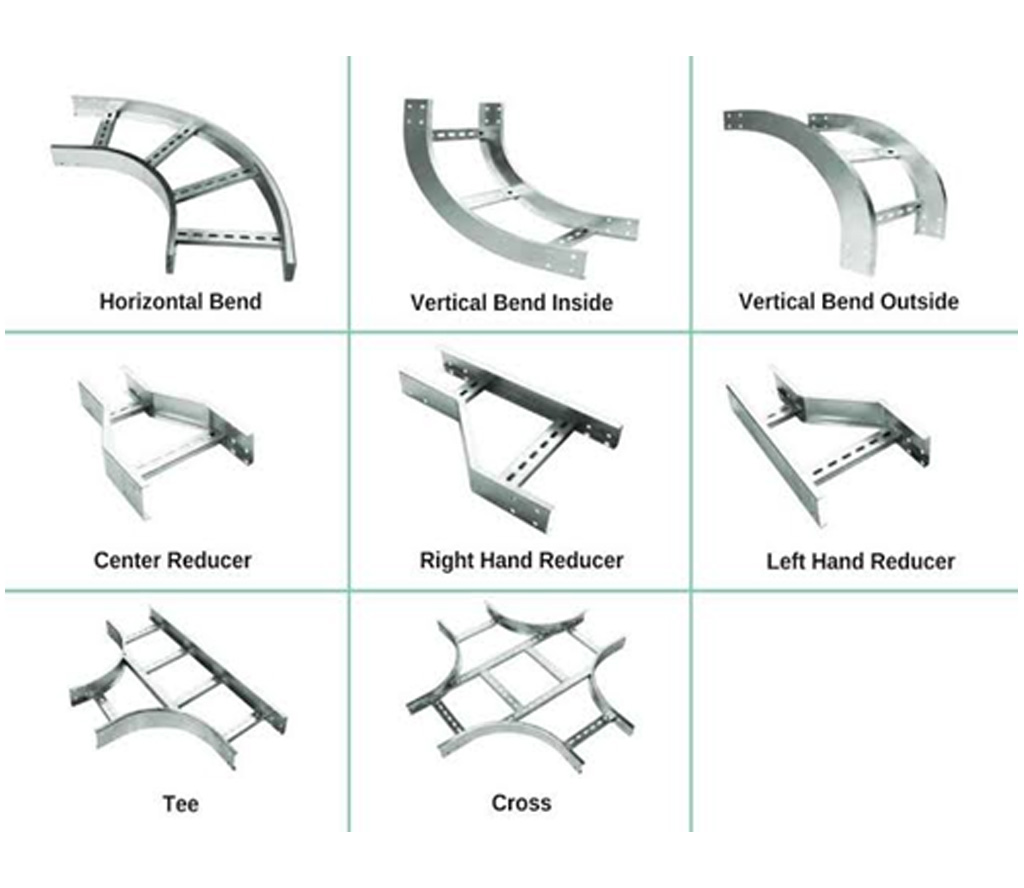

We also supply the complete set of accessories including verticals horizontal bends, reduces & tees .To complement its cable tray offering . Trieti enterprises supplies versatile support systems that are economical ,fully adjustable & reusable . They are quite easy to install, these are the best suited for multipurpose applications in electrical instrumentation & mechanical systems.

A cable tray system is used to support insulated electric cables used for power distribution & communication.

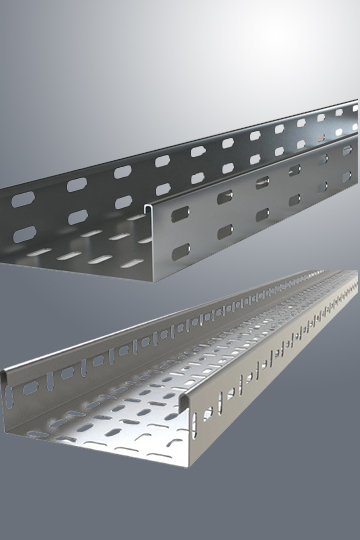

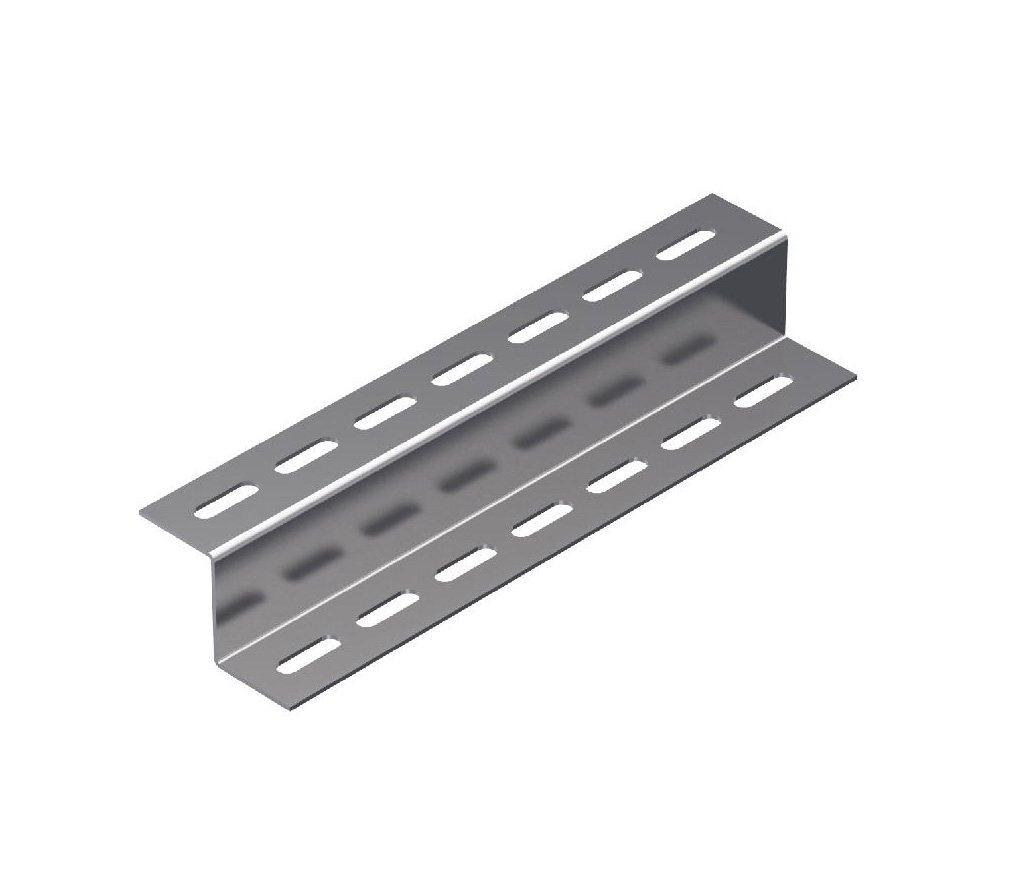

Perforated Cable Tray

Perforated cable trays are a type of cable management system designed to support and organize electrical cables and wires in various installations. They are widely used in commercial, industrial, and residential applications for managing power and data cables. Here’s a comprehensive overview of perforated cable trays:

We offer the most extensive range of perforated type cable trays, which are used for the installation of cables, smaller & controlled cables. These trays can accommodate large number of branch lines and have high load-bearing capacity.

Perforated cable trays can be hung using a center rod support, C-hanger or two-trapeze configuration. They can also be mounted on wall using brackets. For further security, these cable trays are also available with covers. We can also customize the products depending upon the specific requirements.

The perforated design allows for optimal airflow around the cables, which helps in heat dissipation and prevents overheating. Perforations provide convenient points for accessing cables, making it easier to make adjustments, add or remove cables, and conduct maintenance.

Specifications :

| Width | : 50 to 1250 mm |

|---|---|

| Thickness | : 1.0 – 2.0 MM |

| Height | : 25 to 150 mm |

| Bend | 10 to 25 mm |

Cable Tray Manufacturing Standards.

| IS | : 4759/2629/2623 |

|---|

S.S. Cable Tray

Material used is s.S sheet from 1.0 mm to 2.0 mm thickness, which are used in pharmaceutical & food industries where anti rust environments needs to be maintained as per government norms.

Alluminium Cable Tray

Here base material used is aluminum. In some industries, where there is magnetic impact of other machinery and also where weight has to be kept minimal in it industry there such cable trays are used.

M.S. Cable Tray

Here base material used is M.S. Where trays are need to be hot dipped as per the environmental condition of humidity and other industries in coastal areas.

G. I. Pregalvoinzed Cab Le Tray

Material used is G. I. sheet from 80 -180 gsm sheets, these material is most commonly used in industry at almost all sectors of industries, as it being cheaper and long lasting. Thickness of cable tray material ranging from 1.2-2.0 mm thickness.

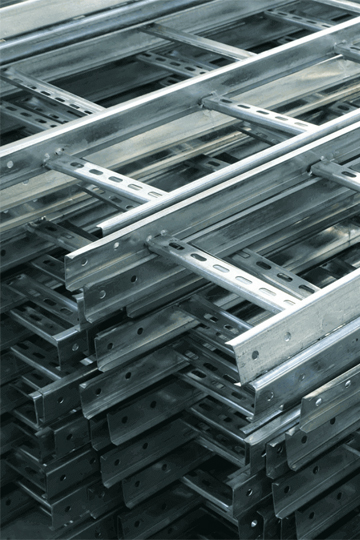

Ladder Tray

Ladder trays consist of two side rails connected by rungs or crossbars, resembling a ladder. This design provides a strong and stable framework for supporting cables.

Ladder trays can be easily extended or modified to accommodate changing cable requirements. Additional sections and accessories can be added as needed.

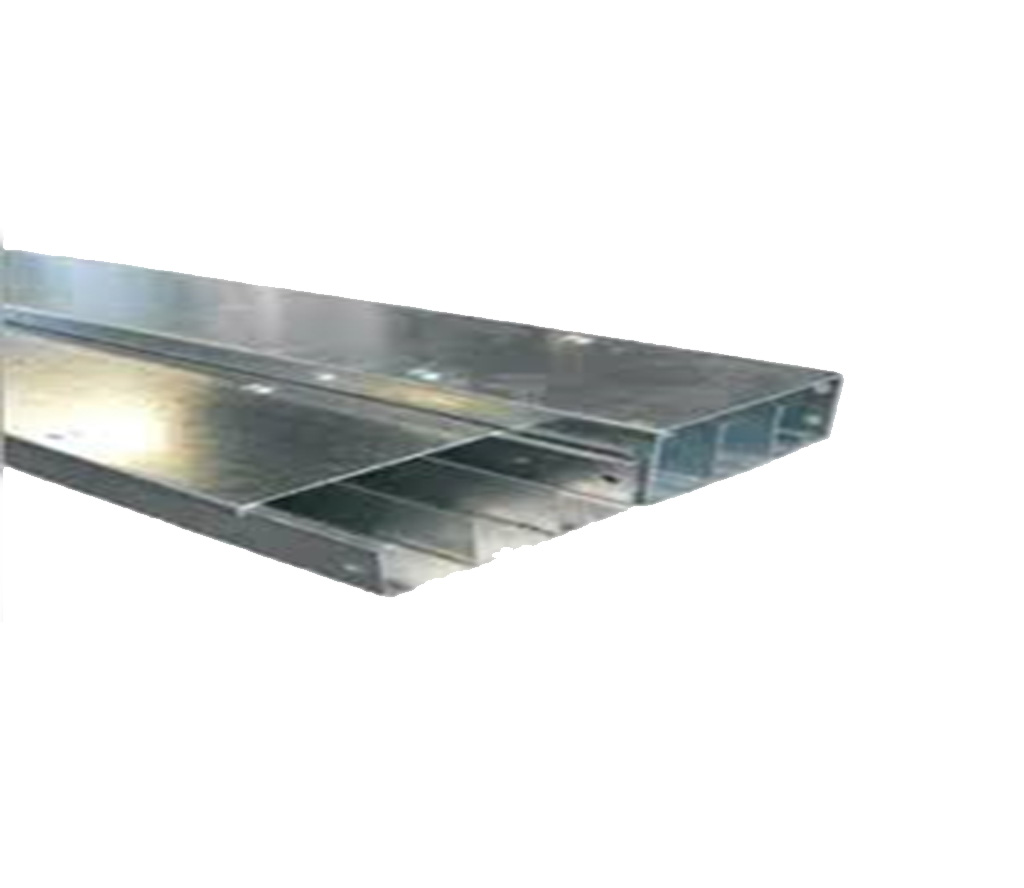

Raceways

Raceways are integral components of modern electrical systems, providing a structured pathway for routing and protecting electrical cables and wires. Designed to shield cables from physical damage, environmental hazards, and electromagnetic interference, raceways help maintain organized and efficient wiring installations

It is available in different configurations, such as surface-mounted, underfloor, and embedded types, catering to diverse installation needs. By concealing cables, raceways enhance the aesthetic appeal of spaces, facilitate maintenance and upgrades.

Cable Tray Accessories

Accessories is designed to work in tandem with their cable tray systems to provide even more effective solutions for cable management in terms of both routing and support